METALLIZATION OF COSMETIC PACKAGING

Metallization of cosmetic packaging involves coating the surface of the plastic with a layer of metal. Thanks to the atomisation of the aluminium microparticles, a very thin coating can be achieved, faithfully reproducing the shape of the component surface. Decorating with this technology is a very convenient way to achieve uniform surfaces with a metallic appearance. The metallization of cosmetic packaging and the application of coatings to product packaging is chosen by many companies and cosmetic brands that want to stand out from the competition

Metallization of cosmetic packaging in the beauty industry

The classic colours that are most commonly used in vacuum metallisation are gold, silver and copper.

Metallization of cosmetic packaging not only improves the aesthetics of the packaging, but also increases its durability, protecting it from scratches and damage. Thanks to these properties, the technique is widely used for the packaging of perfumes, make-up and skincare products, enhancing their visual value and perceived quality.

Gold metallization for cosmetic packaging gives a luxurious look that connotes prestige and exclusivity, attracting customers looking for high quality products. In addition, the gold colour increases the perceived value of the product, which can influence a higher price and increased sales

Silver metallization is the most popular solution in the cosmetics industry. It adds elegance and sets your packaging apart from other brands without applying decoration.

The copper colour is a great choice in cosmetic packaging. Copper is associated with elegance, luxury and high quality, which attracts customers looking for premium products. In addition, compared to more popular colours such as white, black or gold, copper is less common, which helps to distinguish the product on the shop shelf.

The Gun metal colour combines the subtlety of black and the shine of metal, making the packaging look professional and stylish. This colour is a perfect match for both men’s and women’s products, thanks to its versatility and neutrality.

What is metallization of cosmetic packaging? Packaging coating

This process takes place in a vacuum chamber, where the metal is vaporised and deposited on the surface of the packaging material, forming a thin, uniform layer. Vacuum metallization, the application of coatings to product packaging, allows not only an attractive appearance, but also additional protection against external factors such as moisture, oxygen or UV light.

Vacuum metallization also achieves high-quality decorative effects, making products more visually appealing to consumers. As a result, the technology is widely used in the cosmetic, food, pharmaceutical and many other industries where packaging aesthetics and functionality play a key role.

Vacuum metallization of cosmetic packaging

Metallised packaging stands out on shop shelves, catching the eye of customers and making products more appealing. This type of packaging is also more resistant to scratches and damage, which protects the cosmetics and ensures a longer shelf life. Finally, metallization can also affect a positive tactile experience, adding elegance and sophistication to products.

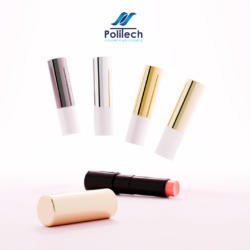

See the effects of metallization on our standard products – perfume closures!

The effect before and after metallization

The effect before and after metallization is clearly visible in the visualisation, which simulates the changes that occur in the appearance of the surface after the metallization process has been applied.

This visualisation makes it possible to compare the original condition with the final result, showing the difference in texture, gloss and colour intensity. This allows an accurate assessment of how the metallization of cosmetic packaging affects the aesthetics and final appearance of the product.

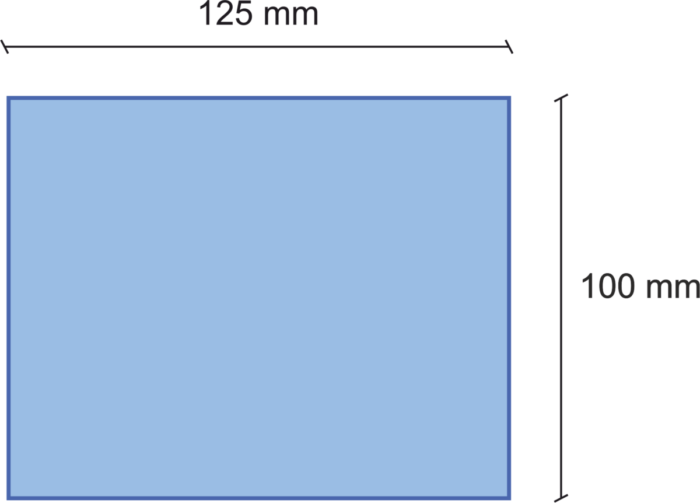

Workpiece dimensions for metallization

Packaging metallization services are strictly dependent on the dimension of the workpiece, as the process requires the technology to be precisely matched to the size and shape of the workpiece.

Accurate determination of the dimensions of the workpiece is key to optimising the metallization process and ensuring high quality of the final product.

See the maximum dimensions of the workpiece for which we can make the decoration..

Contact us:

Metallization of cosmetic packaging – examples:

Vacuum metallization is an advanced technique for applying metallic coatings to surfaces that is widely used in the cosmetics industry. This process helps to give the packaging a luxurious and aesthetically pleasing appearance, as well as increasing its durability. Here are some examples of the use of vacuum metallization on cosmetic packaging:

- Caps and lids

The lids and caps of cosmetics, such as face creams and lotions, are often coated with metallic finishes. Vacuum metallization produces a uniform, smooth surface that looks attractive and adds prestige to products. - Tubes and containers

For tube-shaped packaging, vacuum metallization can be used to create a shiny, metallic effect across the entire surface of the tube or container. This technology makes it possible to create packaging that is both aesthetically pleasing and functional, while protecting the contents from external factors. - Packaging for food supplements

Metallizing the closures of dietary supplement packaging is an increasingly popular solution that combines functionality with aesthetics. This process involves applying a thin layer of metal to the surface of the closures, giving them an attractive metallic appearance and additional protection.

Gallery: