“Good morning. I would like to order a specific quantity of caps for perfume bottles X in colour XX for tomorrow”. We answer such calls and e-mails very often in the Politech sales department. We always appreciate contact with our customers but at the same time we cannot meet the requests for the purchase of products in stock. Why is that so? It’s simple. We do not any stock products. Each product batch is made per order which is much more beneficial than selling stock products.

Sales of standardised products by Politech

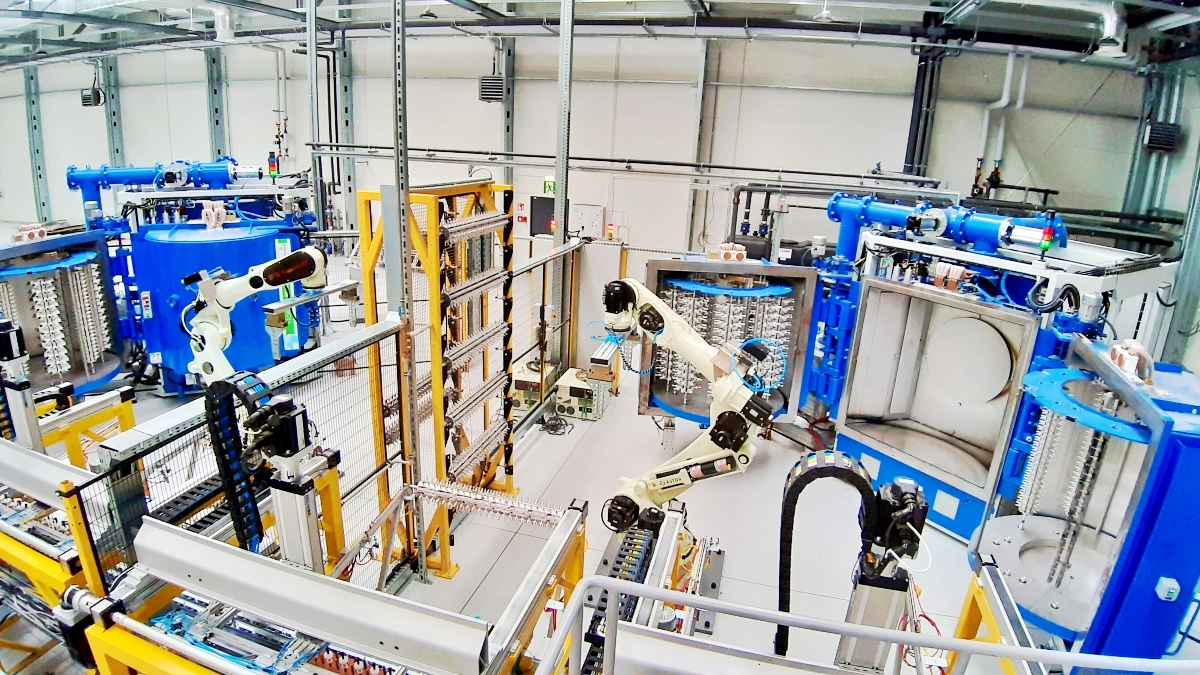

Streamlined communication between the Politech sales personnel and the customers is the basis for sales of standardised products in Politech. The first step in the process of ordering a standardised product is a request sent by the customer. In return, the customer receives all the information on the estimated date of delivery, the price for the products and the available colours and styles. After selecting the colour, type of varnish or metallic finish, the customer receives the final offer; after the customer’s acceptance, we start production.

Benefits of bespoke production

This business model comes from years of experience and was inspired by opinions of our customers who themselves pointed out the advantages associated with such a method of operation. What are the benefits? Low prices, higher quality of products, and full customization of products and production quantities exactly matching our customer’s requirements.

Where do these benefits come from? The prices for the products made in advance would have been much higher because our company would have to pay for storage, including the extension of the storage area, the utilities, the wages for the increased number of personnel, costs of purchase of warehouse equipment and operational costs. Moreover, that would bring about the need for compensation in the product prices for the money “frozen” in the products already made and being stored.

What is the impact of the prolonged product storage on the product’s quality? The longer the product is stored, the more stock taking and inspection procedures it takes, the higher the risk of damage to the product, or simply ageing, such as product fading or yellowing. Obviously, such ageing processes take years to occur but without the ability to predict the quantity of orders, the products in stock would not pass our stringent quality tests due to prolonged storage. And that would lead to the need for extra production, which in turn would result in higher product prices… Apart from that, it would lead to keeping a specific number of the particular product in stock which would have led to the need for extra production.

If there were products in stock, it would have been almost impossible for us to offer customized products. The customer’s choice would be limited only to the colours and styles available in stock.

Undeniable advantages

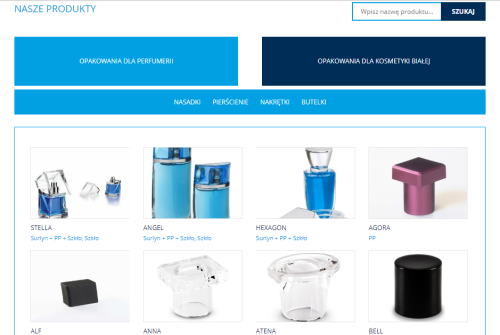

Politech offers standardised products such as caps for perfume bottles, rings and jars for cosmetics. Every item and even individual parts of the items may be ornamented using the following methods: vacuum metallization, UV varnishing, hot-stamping or full body colouring. Other options available: matt finish, glitter or pearl effect. That way, the range of possibilities is really huge and if we sold stock products, it would hamper the imagination of our customers and limit our development.

We are looking ahead and seeking new technologies and personalisation possibilities, so we chose bespoke production as the sales formula. With increasing number of possible designs, colours for metal coating and new standardised products in our range this is the best sales system for us. We are open to any suggestions on improving the purchase process and on any other opportunities to meet your expectations.

Powrót do listy artykułów