As a society, we are used to the fact that we are surrounded by plastics far and wide. Sometimes, however, “plastics” are hiding from us so well that at first glance we cannot judge whether they are not by chance made… of metal. This happens for example in the case of objects subjected to metallization which, after the cosmetics packaging industry, bests many other industries.

What is metallization?

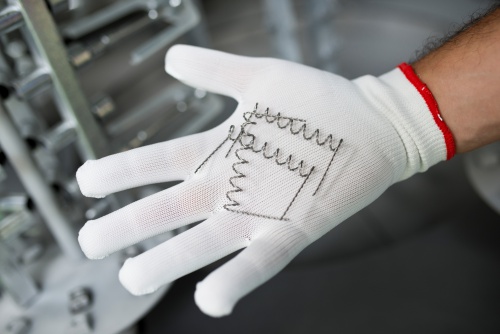

Most plastics can be decorated in many ways, so they are considered to be very versatile. One of the most popular methods of such decoration is metallization. But what is metallization itself? It consists in applying a very thin layer of metal to the surface of previously prepared plastic. Interestingly, such a process changes not only the external appearance of the object, but also affects its physical properties!

Metallization provides increased hardness, resistance to damage such as abrasion or higher temperature resistance. In addition, the metallization of the detail protects the material against the influence of light or chemical compounds.

Types of metallization

Several metallization methods have already been used in industry, and this branch is growing all the time. While there are not many new methods, existing ones are subject to numerous upgrades, automation and other operations that make the process more and more stable and very effective.

Metallization can be applied via spraying, galvanic, contact and diffusion methods. There is also a fire method in which the object is immersed in liquid metal. Politech specialises in the metallization of cosmetic packaging of various types, using the vacuum metallization method. The company has two painting lines and two metallizers adapted to medium and large orders for both silver and colour metallization. In addition, in the new plant in Bydgoszcz Industrial and Technological Park, Politech created an automated painting line combined with two metallizers, adapted to large-series orders.

Advantages of plastic metallization

The shiny, almost mirror effect or interesting matte surface obtained by metallization are not the only advantages of this type of decoration. Politech has many years of experience in preparing colour metallization. This operation not only emphasises the luxury of the packaging, but also allows for distinguishing and individualising the design. Blue, red or even black metallization allows for perfectly matching the decoration to the character of the product.

An undoubted advantage is also the similarity of metallized details to real metal. More and more often in our surroundings we can meet seemingly metal objects that are actually metallized plastic. Elements made of metallized plastic are easier to manufacture than their metal counterparts. They are also much cheaper! This is why one such interesting solution is cheap, metal-like disposable cutlery subjected to this method of decoration.

Metallization around us

In addition to the market of cosmetic and perfumery packaging, metallization is also often used in other industries. Probably the most metallized items around us are found in the cars that we drive. Car headlights have metallized reflectors that direct the reflected rays of light in the desired direction. Due to the excellent reflective properties, this method of decoration is also used in the production of lamps and lampshades. House ornaments and handles in the furniture industry are also increasingly becoming subject to metallization.

Metallization is also used in many household appliances and modern electronics. This method is further used by the aerospace, shipbuilding and telecommunication industries. In your environment you will easily find metallized objects during Christmas, because it is one of the most popular methods of decorating Christmas balls.

Powrót do listy artykułów