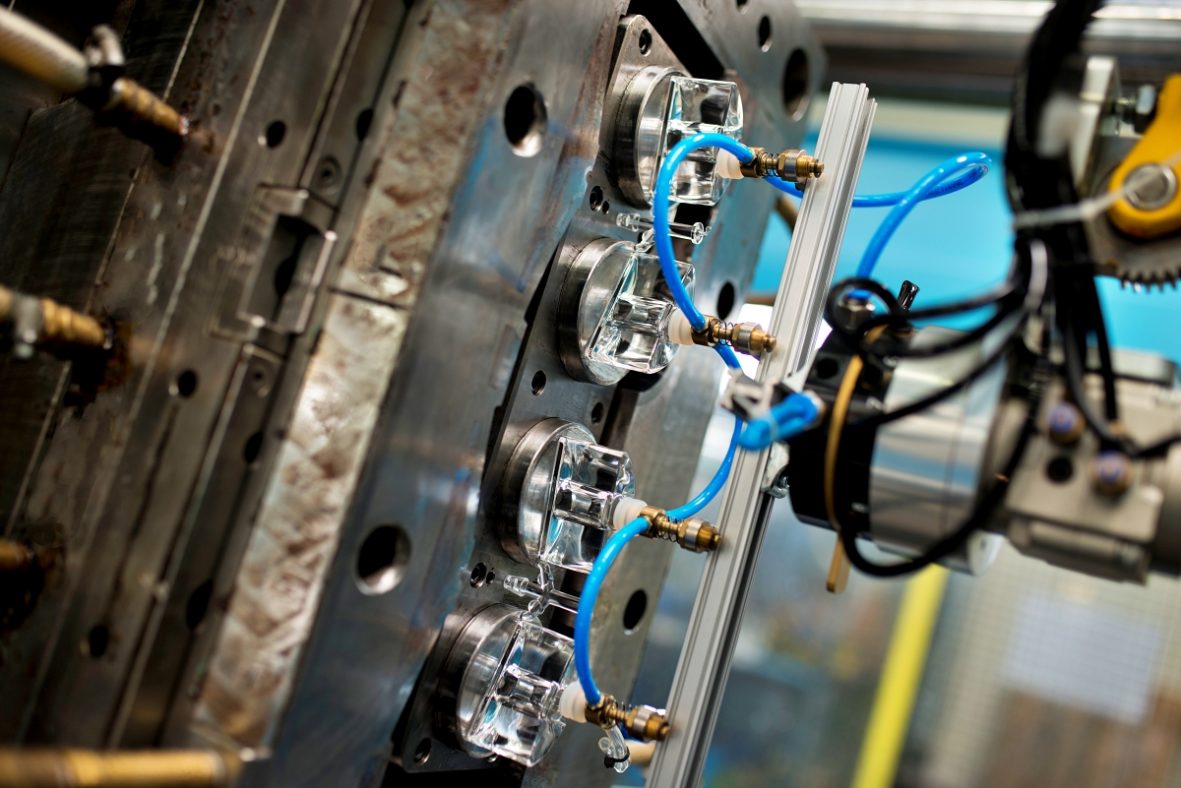

Creating production injection moulds in a facility without a tool shop is a huge challenge. Managing a company department that must simultaneously secure ongoing production and create new moulds may generate delays and many other unforeseeable events. Ultimately, however, the development of our company in this direction is proving to be very beneficial, as it gives us unlimited control over the whole process – from the idea to the finished product. So how do we use this competitive advantage at Politech?

Production of injection moulds, i.e. the benefits of possessing a tool shop

Comprehensive customer service is a dream for many companies. However, some companies add services to what they offer only to attract prospects to their main sources of revenue. However, such changes should be dictated by market requirements and the desire for continuous development. From the very beginnings, we based Politech’s operations on the assumption of having our own tooling department. This was to ensure complete control over the injection mould creation process and, consequently, the possibility of quick repairs to moulds on site as well as offering real customer support in the project development process, from the initial idea to the finished product.

We are committed to full cooperation with our business partners and offering them access to information on their injection moulds as well as those moulds created for individual orders. Our openness and increase in customer awareness during the production process right from the injection mould creation stage has resulted in increased trust towards our company.

This, in turn, has translated into a growing number of individual orders, becoming one of our essential specialities. The largest global cosmetic companies have “made themselves comfortable” in our facility, appreciating the ability to control the production process through one supplier, from the idea to the finished product.

Invaluable toolmaking experience

An on-site tool shop also provides a number of advantages that no external tool shops can ensure. This is because our personnel form a vast repository of knowledge about the creation of moulds and the tools necessary for the cosmetic product packaging manufacturing business. Like any industry, this one has numerous specifications, and the years of experience of our qualified staff protect us from unnecessary losses of time and the avoidance of mistakes. Our understanding of the cosmetic market, the requirements of the companies, as well as the requirements of the final client means that having a tool shop focused on the production of moulds for cosmetic product packaging has become the biggest competitive advantage here at Politech.

Development using the tool shop

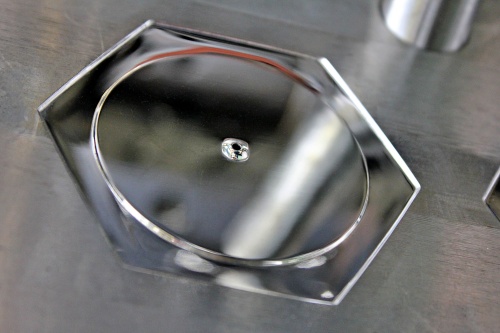

It is also worth remembering that our tooling department is not only able to create new injection moulds. Many other tools and the small elements necessary for the production or decoration processes are also manufactured here. Ongoing support of the paintwork line and preparation of elements used in the process of metallisation, or continuous support for the assembly department, are only few of the benefits of such collaboration between departments.

Politech – European Leader

Thousands of small tools, hundreds of mechanical devices, numerous and increasingly automated machines all constitute equipment that can be useful in many crisis situations at a production company. When well-managed, a tool shop does not have to be a disadvantage, and it can actively support various departments.

Ultimately, our tool shop is not only a means to creating injection moulds, but also serves as a back-up facility for the entire company. This is also why customers can access full knowledge about their moulds and our production potential for standard and customised products. The free flow of information allows our partners to plan short- and long-term activities more precisely. So working with us at Politech means not only high quality production and decoration, but also a full range of information on current production or work in the tooling department. These are the strongest competitive advantages that ensures we remain a European leader in our industry.

Powrót do listy artykułów