For the past few months the world has been struggling with serious problems due to the crisis caused by the SARS-COV 2 pandemic. When the threat to the lives and health of many people is mentioned as the most serious danger of this crisis, it also raises concerns about the state of the economy. The lockdown of almost all global markets has resulted in serious losses for companies and massive layoffs. Many countries immediately introduced actions intended to support employees and employers, but even such measures cannot save many businesses. How are the cosmetics and packaging industries handling this difficult time? We can see that, once again, they are taking advantage of their huge versatility and flexibility.

The virus that changed the world

The first cases of coronavirus in Europe were discovered in January, although at the time they were considered as exceptions that could not affect the spread of the disease across the continent. However, over time, the number of cases continued to grow and it became necessary to take action. The situation appeared to be worse than expected, as during the first phase of the pandemic many of the people who were spreading SARS-CoV-2 were originally diagnosed with pneumonia or severe complications from flu. Eventually the situation developed to a point where its scale became unprecedented. More and more countries, including Poland, started introducing tight restrictions with the aim of preventing the transmission of the disease. Closed borders, the suspension of international and even domestic flights, orders to stay-at-home, bans on meetings with friends, closures of schools, restaurants and shopping centres, restrictions on public transportation and the maintenance of a safe distance – all these restrictions have changed the lifestyle in Europe and many other countries around the world in a way no one could expect.

Empty Wuhan streets during pandemic

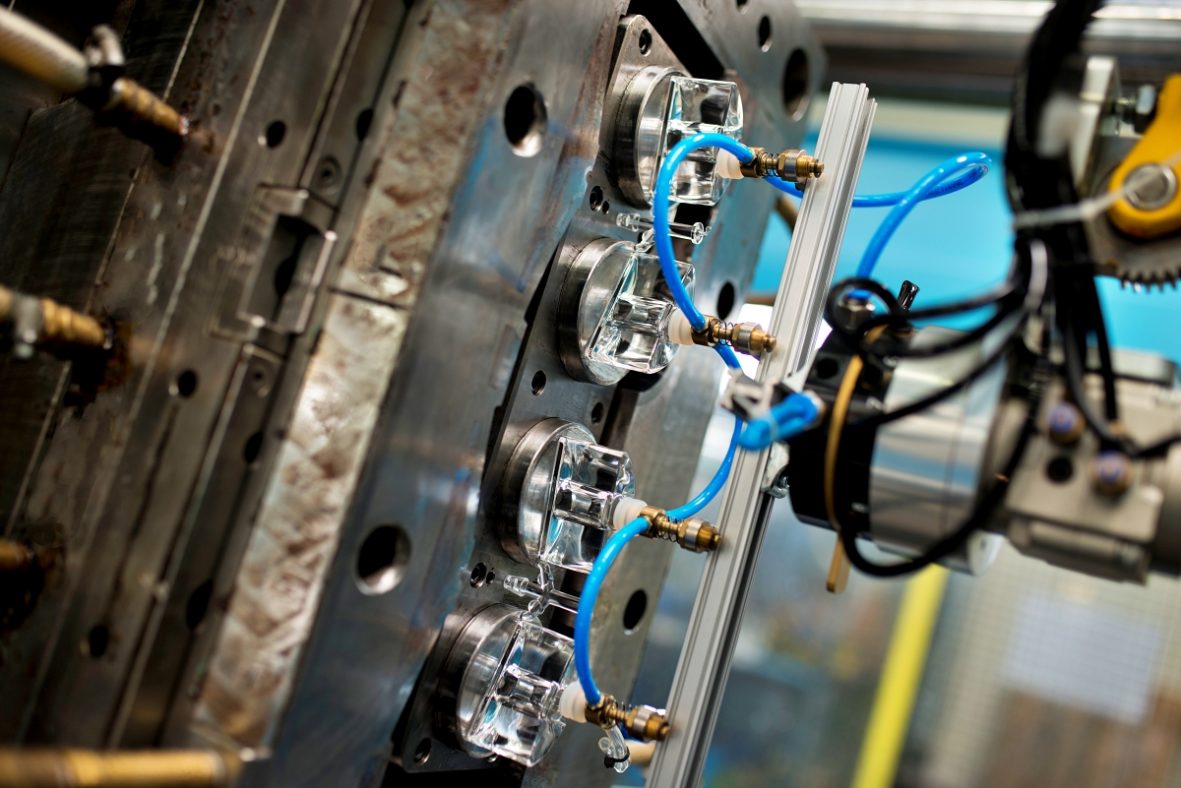

OUR OWN TOOL SHOP – A HUGE ADVANTAGE IN THE INDUSTRY!

Versatility of cosmetic companies

The uncertainty of employees about their positions and a fear of an expanding financial crisis in the coming months instantly stopped many industries from functioning in the market. The sales of essential products jumped. Grocery stores were filled with people, although the items disappearing from the shelves were only a small part of the available products. Shopping for items that were not important for the health became irrelevant. This meant that the cosmetics industry was also severely affected. However the brands offering antibacterial soaps and similar solutions had to set to work.

Fortunately the cosmetics industry was able to prove the extent of its flexibility. It took many brands about two weeks to switch production to the most essential items. The demand was so strong that nobody had to worry about poor sales. Even though store shelves were continually restocked, they still seemed empty…

Fragrance companies that deal with alcohol-based substances on a daily basis seamlessly transformed their manufacturing process to the mass production of disinfectants. Companies offering skin-care cosmetics switched focus to antibacterial soaps and gels. Importantly, despite the crisis, many of those companies showed great courage and donated some of their products to institutions in desperate need of them.

The spiral of fear – how can we revive consumerism?

The demand over time for such products has decreased, so that many companies have returned to their regular manufacturing processes. Of course we must restore the good shopping habits of consumers that we observed before the pandemic. A fearful society refrains from buying non-essential products, and such behaviour increases the downward spiral. Customers do not buy, companies do not produce or earn money, companies lay off their employees, then customers who are unemployed become more resistant to shopping, companies do not sell, etc. The situation can return to normal only if this trend is reversed. Companies are now seeking different ways of increasing their sales, to maintain their turnover at the same level.

Politech injection moulding plant – more than cosmetic packaging

Companies that produce cosmetic packaging, such as Politech, can also be versatile. One of Politech’s greatest assets is their own tool-room and varnish line with vacuum metallisation. This scope of business significantly increases the company’s chances of making it through the crisis unscathed. Moreover, any company which manufactures cosmetic packaging on a daily basis can easily create injection moulds for completely different types of product. Production based on 23 injection moulding machines can be used to smoothly create items for different industries, and we often support our business partners in manufacturing products outside our core business area.

Once we, as a society, have learned how to co-exist with the pandemic, the adaptation of companies to work in different areas seems to be the best way of moving past the crisis. Similarly to the chemical and cosmetic companies that proved their versatility during the period when the number of cases was growing, the packaging companies which process plastics were there to support them. We should bear that in mind, so that everyone can work together to help overcome this crisis. It has been many years since we have experienced such a situation that changed the global economy so drastically.

Powrót do listy artykułów

photo

photo photo

photo