Known as far back as antiquity (Egypt, Mesopotamia, Rome), valued in the Middle Ages and in the Renaissance, loved at the court of Marie Antoinette and sought after during Napoleon Bonaparte’s era, perfumes used to be composed only from essences of natural origin and by artists. Today, they are made in bulk by cosmetic companies (Estée Lauder, L’Oréal, LVMH or Shiseido) using advanced technologies, fully computerised machines and the most sensitive measurement devices in the production process.

Brief history

The history of the current perfume industry is relatively short as it only began at the end of the 19th century. It is connected with the discoveries made at that time in the field of organic chemistry (for instance the industrial production of vanillin, the development of synthetic musk). Nevertheless, the true revolution came later. In the 1970s, during the age of rampant consumerism, the approach to marketing changed. Consumers wanted a lot and they wanted it right now, while markets attempted to meet these expectations. That trend applied to the perfume industry as well – the growing demand required increased supply, which in turn required reaching for more available, and often cheaper, substances. As a result, the once subtle art of combining fragrances turned to a fully industrialised manufacturing process represented by state-of-the art technologies and the latest scientific achievements.

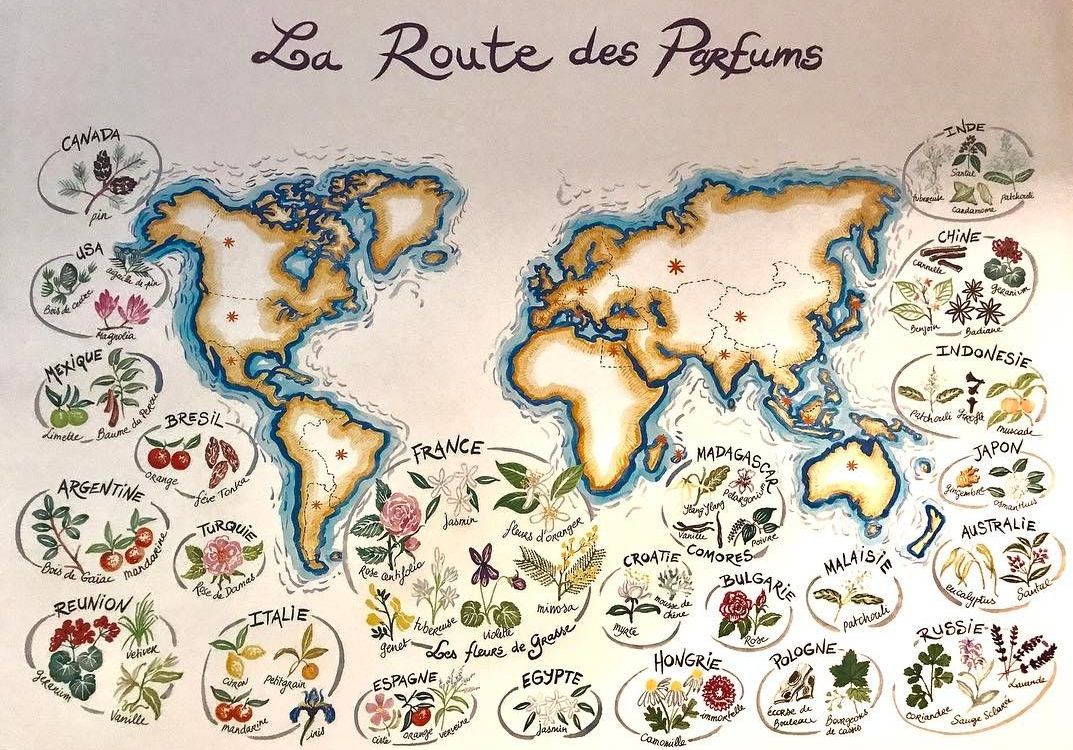

Natural and synthetic ingredients

It is undeniable that the art of composing perfumes still resembles composing music. Together, individual notes yield a harmonious final effect, with the nature, complexity and durability of the fragrance depending on the type and quantity of ingredients – whether natural or synthetic. The former are mostly flower (and flower bud), fruit, bark, seed, resin, leaf or grass extracts (oils). There are also ingredients of animal origin, such as ambergris (secretion from the gastrointestinal tract of the sperm whale), castoreum (exudate from the castor sacs of the European beaver), honeycomb or musk as well as lichen. Synthetic ingredients permit creating fragrances that are not present in nature. The properties of synthetic substances offer almost unlimited possibilities in terms of obtaining various components and creating the substitutes of natural ingredients (e.g. white musk) or copying natural fragrances which cannot be obtained from their original source (e.g. the fragrance of lily-of-the valley).

Extraction

This process is indispensible in obtaining the essence from natural ingredients. There are a number of commonly used methods. Extraction with the participation of an organic compound, isolating the fragrance molecules from the material, is the most popular and is considered to be the most economical method. Plant raw material (flowers, buds, grass, leaves) is usually subject to steam distillation, while dry distillation is used to obtain the extract from tree bark and materials of animal origin. Another method is cold pressing but it is mostly used for citrus fruit.

Synthetic ingredients are created in laboratories and are composed by perfume chemistry specialists. Their properties are the outcome of precise calculations, tests and measurements. Such ingredients are valued for their repeatability and stability, which is hard to obtain for natural components (the quantity of ethereal oils in plants depends, for instance, on the weather conditions in a particular season).

Blending of ingredients and aging

The next stage involves blending the components. Creating one specific fragrance is an onerous process, requiring the skills of a specialist known as “the nose” – a perfume master. A finished composition is then combined with alcohol and water. The concentration of fragrant oils and the quantity of the solvent added differ depending on whether the final product is to be a cologne, eau de toilette or maybe another variant (perfume proper means a mixture containing about 40% of the fragrance essence). Finished perfumes “rest” for some time – it is a stage where the ingredients finally bind with one another.

Does the manufacture of perfumes end with the creation of a fragrance?

No, it is just the beginning. Today, you need more than just compose a fragrance and pour it into bottles. Some added value is needed – a comprehensive marketing plan oriented towards the recipient’s needs, a specific philosophy and proper packaging that will make the customer want the perfume even before putting it on their skin and checking the fragrance.

Powrót do listy artykułów